Low scale reheating of semi-finished metal products in furnaces with a central recuperator

4,90 €

Auf Lager

Artikelnummer

00541_2016_03_02

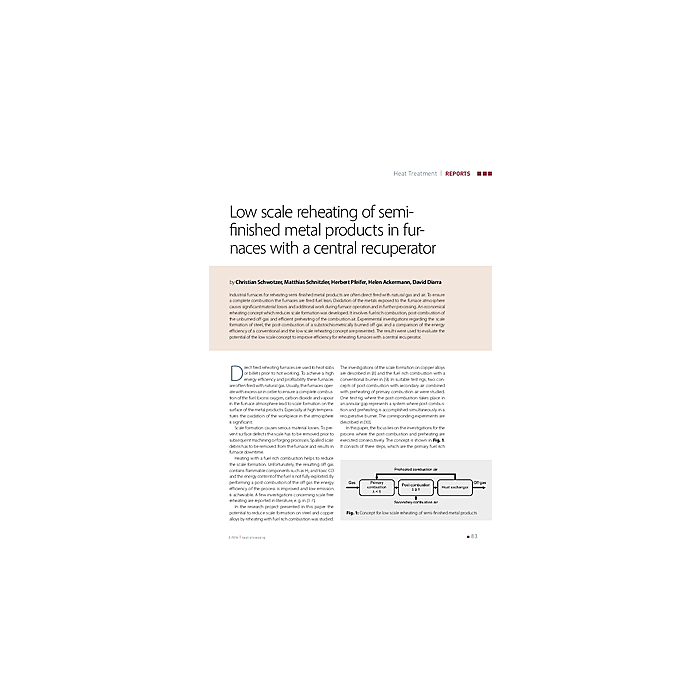

Industrial furnaces for reheating semi-finished metal products are often direct fired with natural gas and air. To ensure a complete combustion the furnaces are fired fuel lean. Oxidation of the metals exposed to the furnace atmosphere causes significant material losses and additional work during furnace operation and in further processing. An economical reheating concept which reduces scale formation was developed. It involves fuel rich combustion, post-combustion of the unburned off-gas and efficient preheating of the combustion air. Experimental investigations regarding the scale formation of steel, the post-combustion of a substoichiometrically burned off-gas and a comparison of the energy efficiency of a conventional and the low scale reheating concept are presented. The results were used to evaluate the potential of the low scale concept to improve efficiency for reheating furnaces with a central recuperator.

| Autoren | Christian Schwotzer / Matthias Schnitzler / Herbert Pfeifer / Helen Ackermann / David Diarra |

|---|---|

| Erscheinungsdatum | 01.03.2016 |

| Format | |

| Zeitschrift | heat processing - Ausgabe 03 2016 |

| Verlag | Vulkan-Verlag GmbH |

| Sprache | English |

| Titel | Low scale reheating of semi-finished metal products in furnaces with a central recuperator |

| Beschreibung | Industrial furnaces for reheating semi-finished metal products are often direct fired with natural gas and air. To ensure a complete combustion the furnaces are fired fuel lean. Oxidation of the metals exposed to the furnace atmosphere causes significant material losses and additional work during furnace operation and in further processing. An economical reheating concept which reduces scale formation was developed. It involves fuel rich combustion, post-combustion of the unburned off-gas and efficient preheating of the combustion air. Experimental investigations regarding the scale formation of steel, the post-combustion of a substoichiometrically burned off-gas and a comparison of the energy efficiency of a conventional and the low scale reheating concept are presented. The results were used to evaluate the potential of the low scale concept to improve efficiency for reheating furnaces with a central recuperator. |

Eigene Bewertung schreiben