Numerical simulation of inductive longitudinal HF welding of cladded pipes

4,90 €

Auf Lager

Artikelnummer

00541_2019_04_04

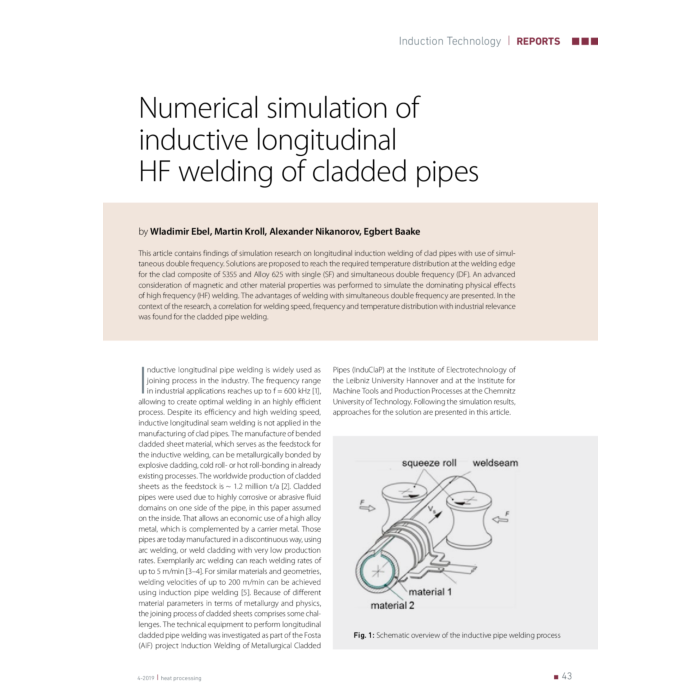

This article contains findings of simulation research on longitudinal induction welding of clad pipes with use of simultaneous double frequency. Solutions are proposed to reach the required temperature distribution at the welding edge for the clad composite of S355 and Alloy 625 with single (SF) and simultaneous double frequency (DF). An advanced consideration of magnetic and other material properties was performed to simulate the dominating physical effects of high frequency (HF) welding. The advantages of welding with simultaneous double frequency are presented. In the context of the research, a correlation for welding speed, frequency and temperature distribution with industrial relevance was found for the cladded pipe welding.

| Autoren | Wladimir Ebel, Martin Kroll, Alexander Nikanorov, Egbert Baake |

|---|---|

| Erscheinungsdatum | 20.11.2019 |

| Format | |

| Verlag | Vulkan-Verlag GmbH |

| Sprache | Deutsch |

| Titel | Numerical simulation of inductive longitudinal HF welding of cladded pipes |

| Beschreibung | This article contains findings of simulation research on longitudinal induction welding of clad pipes with use of simultaneous double frequency. Solutions are proposed to reach the required temperature distribution at the welding edge for the clad composite of S355 and Alloy 625 with single (SF) and simultaneous double frequency (DF). An advanced consideration of magnetic and other material properties was performed to simulate the dominating physical effects of high frequency (HF) welding. The advantages of welding with simultaneous double frequency are presented. In the context of the research, a correlation for welding speed, frequency and temperature distribution with industrial relevance was found for the cladded pipe welding. |

Eigene Bewertung schreiben